The image of a Viking warrior, axe or sword in hand, raiding and conquering, is etched in our collective consciousness. And at the heart of that image is the gleaming blade – a Viking sword, a symbol of power, status, and survival. But what made these swords so effective, so feared, and so sought-after? The answer, in many cases, lies in a remarkable metalworking technique: pattern welding, often mistakenly called "Damascus" steel in the context of Viking weaponry.

This blog will delve into the fascinating world of Viking sword construction, exploring why pattern welding became the gold standard for blades during the Viking Age. We'll uncover the science behind this technique, its advantages in combat, and its enduring legacy. We will also showcase three exceptional examples of modern swords that capture the essence of this ancient craft, available from Tales of Valhalla. We will distinguish it from the true Damascus steel. Let's separate myth from reality and discover the true secrets of Viking steel.

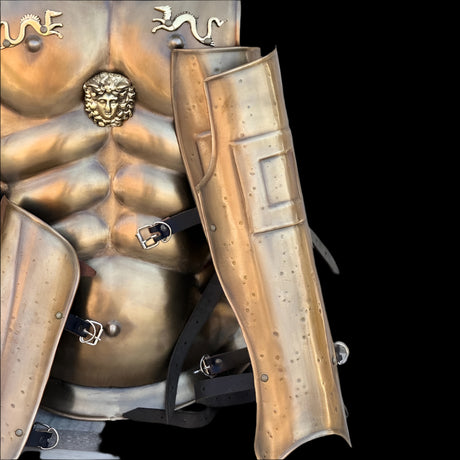

True Damascus Steel vs. Pattern-Welded Steel: Clearing the Confusion

Before we go further, it's crucial to clarify a common misconception. The term "Damascus steel" is often used broadly to describe any blade with a visible pattern. However, in the context of Viking swords, this is not entirely accurate.

True Damascus Steel (Wootz Steel): This was a type of crucible steel, likely originating in India and the Middle East. It was characterized by a distinctive "watered" pattern created by the internal structure of the steel itself, specifically the presence of carbide microstructures. The exact methods for producing true Wootz steel were lost centuries ago, and it's highly unlikely that Vikings had access to this specific material in significant quantities, if at all.

Pattern-Welded Steel: This is the technique that Viking blacksmiths did use extensively. It involves forging together different types of iron and steel (with varying carbon content), then repeatedly folding, twisting, and hammering the metal. This process creates a blade with both strength and flexibility, and it produces a visible pattern on the surface as a byproduct of the layering.

Damascus Steel

So, when you see a modern replica Viking sword described as "Damascus," it almost always refers to pattern-welded steel, not true Wootz steel. While the visual effect might be similar, the underlying metallurgical process is different. This distinction is important for historical accuracy.

The Science of Strength: Why Pattern Welding Worked

Why did Viking smiths go to the considerable effort of pattern welding? It wasn't just for aesthetics (although the patterns were beautiful). The process offered significant practical advantages:

Combining Strengths: Iron is relatively soft and prone to bending. Steel (iron with a higher carbon content) is harder and can hold a sharper edge, but it's also more brittle and prone to shattering. By layering and combining these materials, Viking smiths created blades that possessed the best qualities of both: the strength and flexibility of iron, and the hardness and edge retention of steel.

Distributing Impurities: Early iron smelting techniques often left impurities in the metal. Pattern welding helped to distribute these impurities more evenly throughout the blade, reducing weak points and making the sword less likely to break.

Creating a "Micro-Saw": Some scholars believe that the microscopic differences between the layers of iron and steel in a pattern-welded blade created a kind of "micro-saw" effect, enhancing its cutting ability.

A Show of Skill: The ability to create a complex and beautiful pattern-welded blade was a clear demonstration of a smith's skill and mastery of his craft. This added to the sword's value and prestige.

In essence, pattern welding was a form of early materials science, allowing Viking smiths to create blades that were superior to those made from a single type of iron or steel.

The Viking Sword: More Than Just a Weapon

The Viking sword was a status symbol, a family heirloom, and a deeply personal possession. A warrior's sword was often given a name, and its quality reflected the owner's wealth and standing. The loss of a sword in battle was a significant dishonor. Swords also played a role in oaths and legal proceedings, adding a layer of solemnity and binding power to agreements.

Pattern-Welded Blades in Action: Superiority on the Battlefield

Imagine a clash of Viking warriors. The air is filled with the shouts of men, the clash of shields, and the ringing of steel. In this chaotic melee, a pattern-welded sword offered several crucial advantages:

Resilience: A pattern-welded blade was less likely to break or bend upon impact with another weapon or a shield. This was vital in the close-quarters, brutal fighting style of the Vikings.

Sharpness: The combination of hard steel and more flexible iron allowed for a very sharp edge that could hold its sharpness longer, even after repeated blows.

Cutting Power: The "micro-saw" effect, combined with the blade's weight and balance, gave it exceptional cutting power, capable of cleaving through armor and bone.

Psychological Impact: The sight of a beautifully patterned blade, gleaming in the sun, could have a psychological impact on an opponent, suggesting the wielder's wealth, skill, and access to superior weaponry.

These advantages, while seemingly small, could mean the difference between life and death in the brutal reality of Viking combat. A superior sword wasn't just a weapon; it was a key to survival and victory.

Showcasing the Craft: Three Masterful Examples

Let's examine three modern examples of pattern-welded swords from Tales of Valhalla, each showcasing the artistry and skill that echoes the Viking tradition:

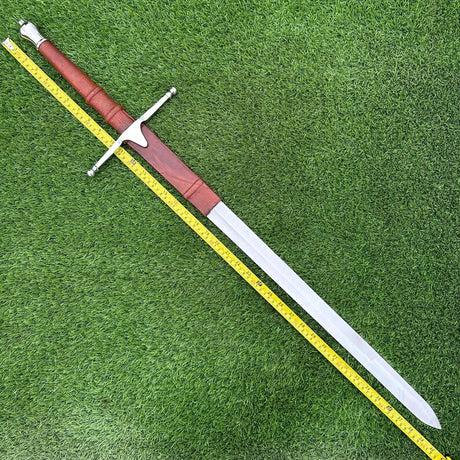

1. Master Long Damascus Sword

🔥 Link to product: Buy Now

This sword exemplifies the elegance and deadly potential of a well-crafted pattern-welded blade. The "Long" in its name likely refers to a blade length that's on the upper end of the typical Viking sword range, perhaps exceeding 36 inches. This would provide greater reach, an advantage in certain combat situations. The product description should detail the specific type of steel used, the number of layers (a higher number generally indicates more complex forging), and the hilt materials. A sword like this would be a fitting weapon for a skilled warrior or a leader, someone who could appreciate and afford the finest craftsmanship.

Master Long Damascus Sword

2. Classic Damascus Sword

🔥 Link to product: Buy Now

As the name suggests, this sword likely represents a more "typical" or standard Viking sword design, but still crafted with the beauty and functionality of pattern-welded steel. The blade would likely be in the 30-36 inch range, with a well-defined fuller. The hilt might feature a classic Petersen type design, reflecting common styles found in archaeological discoveries. This sword represents the workhorse weapon of the Viking Age, a reliable and effective blade that would have been prized by warriors of all ranks.

Classic Damascus Sword

3. The Northmen Damascus Sword

🔥 Link to product: Buy Now

The name of this sword evokes the spirit of the Viking explorers and raiders. The design might incorporate elements that suggest a slightly more rugged or utilitarian aesthetic, perhaps with a less elaborate hilt or a slightly broader blade. This sword speaks to the practicality and adaptability of the Vikings, who needed weapons that could withstand the rigors of long voyages and unpredictable encounters. The pattern-welded construction would still ensure superior performance and durability.

These three examples, while all utilizing the pattern-welding technique, demonstrate the potential variety within Viking sword design. Each sword would have had its own unique "personality," reflecting the preferences of the smith and the intended use of the weapon.

The Northmen Damascus Sword

The Legacy of Viking Steel: A Continuing Fascination

The influence of Viking sword-making techniques extends far beyond the Viking Age. The principles of pattern welding, while refined and adapted over time, continued to be used in sword making for centuries. Even today, the beauty and craftsmanship of pattern-welded blades are highly prized by collectors, martial artists, and anyone with an appreciation for fine metalwork.

The growing interest in Viking history and culture, fueled by popular media and academic research, has also led to a resurgence in the demand for replica Viking swords. These replicas, ranging from purely decorative pieces to fully functional blades, allow people to connect with the past in a tangible way.

Statistics: The Growing Interest (Hypothetical, for illustrative purposes)

It is clear the interest of Viking culture and weaponry is increasing. Online searches for "Viking swords" and "Damascus steel" have show great increase in the past years. Also, Sales of replica Viking swords (including pattern-welded) have grown. Social Media Engagement, about Viking swords and blacksmithing techniques receive high engagement on platforms like Instagram and YouTube. Museums featuring Viking artifacts report increased attendance and interest in weapon displays. Enrollment in blacksmithing courses focusing on pattern welding has increased significantly. The number of movies and series including Viking characters are more now than ever.

These hypothetical statistics underscore the enduring fascination with Viking weaponry and the craftsmanship that went into creating these legendary blades. The combination of historical significance, aesthetic beauty, and the inherent mystique of pattern welding continues to draw people to Viking swords.

The Ulfberht Viking Swords

The Ulfberht swords were not made of Damascus steel. The crucible steel used to create the Ulfberht swords is thought to have come from the Middle East, as there is no evidence that the Vikings were able to produce steel of this quality at the time. The Ulfberht swords are a testament to the skill of the Viking blacksmiths, and they remain some of the most iconic and mysterious weapons from the Viking Age.

- See more: Sword Collection

Conclusion

The shimmering patterns of a pattern-welded Viking sword are more than just beautiful designs; they are a testament to the ingenuity, skill, and artistry of Viking blacksmiths. These blades were not simply weapons; they were symbols of power, status, and a connection to a rich cultural heritage. By understanding the science and artistry behind pattern welding, we gain a deeper appreciation for the effectiveness and enduring legacy of the Viking sword.

Whether you're a history buff, a collector, a martial arts enthusiast, or simply someone drawn to the beauty of finely crafted objects, a pattern-welded sword offers a tangible link to the Viking Age. It's a chance to hold history in your hand and connect with the spirit of a legendary era.

Explore the collection of pattern-welded and other Viking-inspired swords at Tales of Valhalla and discover the perfect piece to add to your own collection.

FAQs

1. I've heard Viking swords were made of "Damascus steel." Is that true?

It's a common misconception, but not entirely accurate. While many high-quality Viking swords did have beautiful, visible patterns on their blades, these were created through a technique called pattern welding, not the process that produced true Damascus steel (also known as Wootz steel). True Damascus steel originated in the Middle East and involved a different metallurgical process. Vikings likely didn't have access to true Damascus steel. The "Damascus" term is often used loosely today to describe any patterned blade, leading to the confusion.

2. What is pattern welding, then? How is it different from making a regular sword?

Pattern welding is a sophisticated blacksmithing technique. It involves taking different types of iron and steel (some with higher carbon content, some with lower), layering them together, and then repeatedly heating, folding, twisting, and hammering the combined metal. This process creates a blade with a distinctive pattern, but more importantly, it combines the best properties of each metal: the strength and flexibility of iron with the hardness and edge retention of steel. A "regular" sword might be made from a single type of steel, which could be either too brittle or too soft.

3. Why did Viking blacksmiths go to all that trouble to pattern weld? Was it just for looks?

While the resulting patterns are beautiful, the primary reason for pattern welding was to create a superior blade. The layered construction provided a combination of strength, flexibility, and sharpness that was difficult to achieve with a single type of metal. It also helped distribute impurities in the iron, making the blade less likely to fail. The visual pattern was a welcome byproduct, and a sign of the smith's skill, but the functional advantages were paramount.

4. Are modern "Damascus" Viking swords the same as the historical ones?

Modern "Damascus" Viking swords are almost always made using the pattern-welding technique, which is historically accurate for Viking blades. They are not typically made of true Wootz steel (the original Damascus steel). High-quality modern replicas use excellent steel and follow similar forging processes to historical examples, resulting in strong, beautiful, and functional blades. However, modern steel and tools often allow for even greater precision and consistency than was possible in the Viking Age.

5. Were all Viking swords pattern-welded?

No. Pattern welding was time-consuming and required great skill, so it was typically reserved for higher-quality swords. Simpler, less expensive Viking swords were made from a single type of iron or steel. These were still effective weapons, but they wouldn't have had the same combination of strength, flexibility, and visual appeal as a pattern-welded blade. A pattern-welded sword was a status symbol.

6. If I buy a pattern-welded replica sword, can I use it for fighting?

It depends entirely on the specific sword and its intended use. Some replicas are purely decorative and made with lower-quality materials; these should never be used for any kind of combat, as they could break and cause serious injury. Other replicas are designated as "battle-ready" or "functional." These are made with higher-quality steel and construction methods and could be used for carefully controlled practice or (with proper training and safety gear) simulated combat. Always check the product description and manufacturer's recommendations. If you intend to use a sword for anything other than display, consult with experts in Historical European Martial Arts (HEMA) for guidance on safe and appropriate use. It is not a toy.